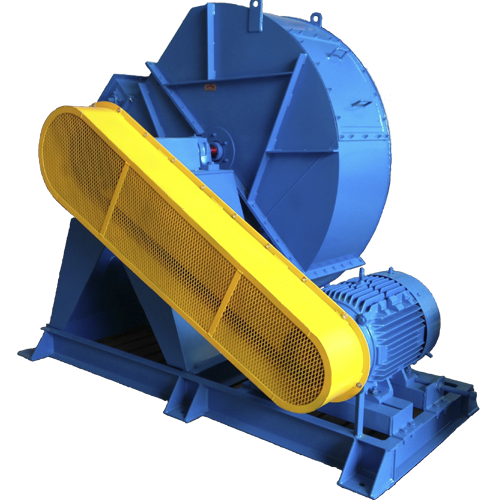

Heavy-duty construction fans with three types of impellers available (backward-curved -E-, backward-inclined -O-, and radial straight -U-). Manufactured in a 9x arrangement with belt drive and the motor mounted on tensioning rails with a channel base.

- Capacity Range: Airflow from 400 to 150,000 CFM.

- Static Pressure: 0 to 40″ W.C.

- Temperature Resistance: Gases up to 150 °C in standard design, 350 °C with cooling disc, 400 °C in stainless steel with cooling disc, 500 °C with insulation, special steel, and cooling disc.

Applications: Dust collection systems. Induced and forced draft in furnaces and boilers. Pneumatic material transport. Cooling of glass and glassware refractories. Recirculation of hot air in ovens. Vapor extraction in the chemical industry, etc.