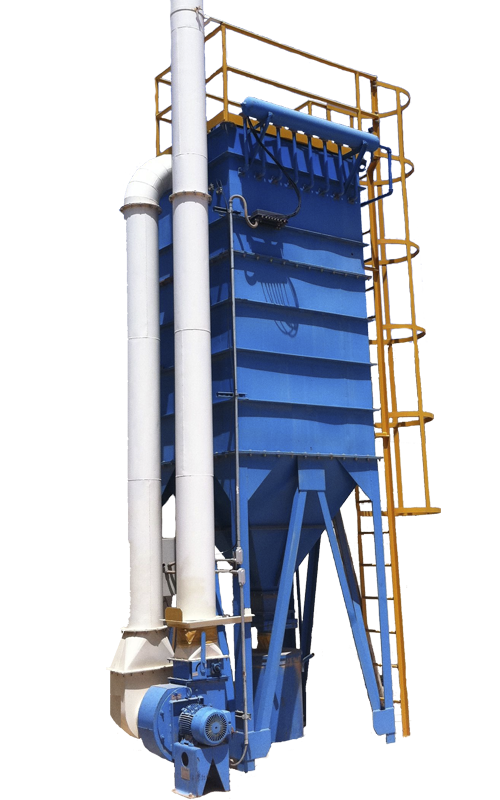

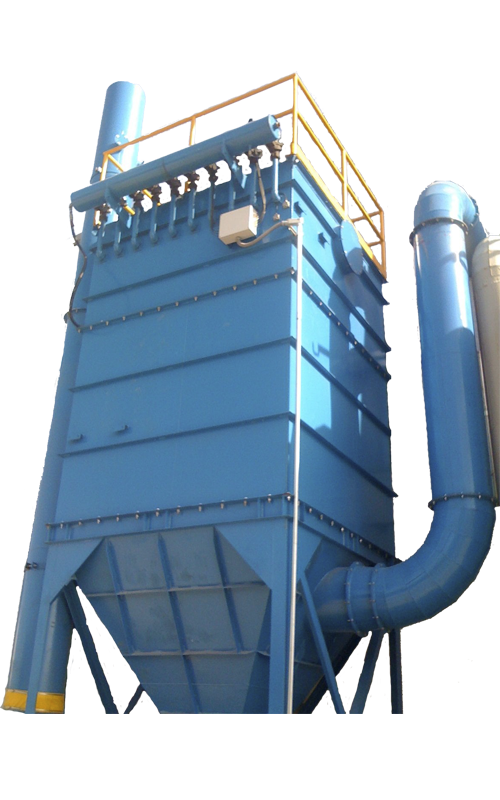

The KNF bag dust collector with top inlet is designed for continuous and automatic operation, using compressed air pulse cleaning system.

The material of the bags used varies depending on the collected dust, as well as factors such as maximum temperature, resistance to abrasion, resistance to acids, tensile strength, and resistance to alkalis.

It has a top inlet, which eliminates upward velocity and improves cleaning efficiency.

- Typical efficiency of 99% for 1-micron particles.

- Temperature resistance: Gases up to 260 °C.

- Capacity range: Airflow from 1,500 to 20,000 cubic feet per minute (CFM) per module.